Fiber Cement Insulated Siding: 7 Ultimate Benefits You Can’t Ignore

Thinking about upgrading your home’s exterior? Fiber cement insulated siding might be the game-changer you’ve been searching for. Durable, energy-efficient, and stylish, it’s no wonder more homeowners are making the switch.

What Is Fiber Cement Insulated Siding?

Fiber cement insulated siding is a modern exterior cladding solution that combines the strength of fiber cement with a layer of rigid foam insulation. This composite material is designed to protect homes from the elements while improving thermal performance and reducing energy costs.

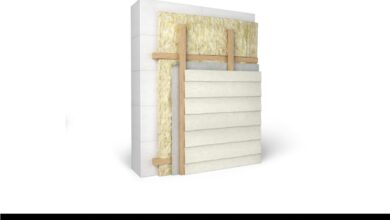

Composition and Structure

Fiber cement insulated siding is made from a blend of cellulose fibers, sand, and Portland cement. The insulation layer—typically expanded polystyrene (EPS) or mineral wool—is bonded to the back of the panel during manufacturing. This creates a unified system that’s both robust and thermally efficient.

- Core material: cellulose fibers, sand, cement

- Insulation types: EPS, XPS, or mineral wool

- Bonding process: factory-laminated for durability

“Fiber cement siding has evolved from a simple cladding to a high-performance building envelope component,” says Dr. Laura Simmons, a materials scientist at the University of Colorado.

How It Differs From Traditional Siding

Unlike traditional fiber cement boards that require separate insulation installation, fiber cement insulated siding comes pre-insulated. This integration eliminates thermal bridging and ensures consistent R-values across the wall surface.

- No need for additional furring strips or separate insulation layers

- Reduced labor and material costs during installation

- Better air sealing and moisture management

According to the U.S. Department of Energy, continuous insulation like that found in fiber cement insulated siding can reduce energy loss by up to 40% compared to traditional cavity-insulated walls.

Top 7 Benefits of Fiber Cement Insulated Siding

Choosing the right siding isn’t just about curb appeal—it’s a long-term investment in your home’s comfort, efficiency, and value. Fiber cement insulated siding delivers on multiple fronts, making it a top contender in modern construction.

1. Superior Energy Efficiency

One of the standout features of fiber cement insulated siding is its ability to improve a home’s thermal envelope. The integrated insulation layer helps maintain indoor temperatures, reducing the workload on HVAC systems.

- Typical R-values range from R-2.5 to R-5, depending on thickness

- Reduces heating and cooling costs by up to 20%

- Helps meet ENERGY STAR and Passive House standards

When paired with proper air sealing, fiber cement insulated siding can significantly lower a home’s carbon footprint. A study by the National Renewable Energy Laboratory (NREL) found that insulated siding can cut residential energy use by 7–14% annually.

2. Exceptional Durability and Longevity

Fiber cement is known for its resilience. It resists cracking, warping, and rotting—common issues with wood and vinyl siding. When combined with insulation, the product maintains structural integrity even in extreme weather.

- Withstands winds up to 130 mph

- Resistant to hail, fire, and insect damage

- Lifespan of 50+ years with minimal maintenance

Unlike vinyl, which can become brittle in cold climates, fiber cement retains its strength across temperature extremes. This makes it ideal for regions with harsh winters or intense sun exposure.

3. Enhanced Moisture and Mold Resistance

Moisture management is critical in any wall system. Fiber cement insulated siding is engineered with drainage channels and moisture-resistant cores that prevent water intrusion and promote drying.

- Non-absorbent material prevents water retention

- Drainage gaps behind panels allow airflow

- Resists mold, mildew, and fungal growth

According to the Environmental Protection Agency (EPA), mold thrives in damp, poorly ventilated areas. Fiber cement insulated siding’s design minimizes these risks, contributing to healthier indoor air quality.

4. Improved Sound Insulation

While often overlooked, noise reduction is a valuable benefit of insulated siding. The dense fiber cement layer and foam backing work together to dampen external sounds.

- Reduces street noise by up to 50%

- Improves acoustic comfort indoors

- Ideal for urban homes or busy neighborhoods

This makes fiber cement insulated siding a smart choice for homeowners seeking a quieter, more peaceful living environment.

5. Fire Resistance

Fiber cement is classified as a non-combustible material, making it an excellent choice for fire-prone areas. It won’t ignite, melt, or contribute to flame spread.

- Meets ASTM E84 Class A fire rating

- Does not emit toxic fumes when exposed to heat

- Recommended for homes in wildfire zones

For more information on fire-resistant building materials, visit the National Fire Protection Association.

6. Eco-Friendly and Sustainable

Sustainability is a growing concern in construction. Fiber cement insulated siding scores well in environmental impact due to its long lifespan, recyclability, and energy-saving properties.

- Contains up to 30% recycled materials

- Low embodied energy compared to aluminum or steel siding

- Reduces reliance on fossil fuels through energy efficiency

Manufacturers like James Hardie and Alside are increasingly using sustainable production methods, including water reclamation and low-VOC coatings.

7. Aesthetic Versatility and Curb Appeal

Fiber cement insulated siding is available in a wide range of textures, colors, and profiles. It can mimic the look of wood, stucco, or masonry without the maintenance drawbacks.

- Options include lap siding, shingles, and panels

- Factory-painted or pre-primed for long-lasting color

- Customizable to match any architectural style

According to a 2023 Remodeling Impact Report by the National Association of Realtors, siding upgrades offer a 90%+ return on investment, with fiber cement being one of the top choices.

Installation Process of Fiber Cement Insulated Siding

Proper installation is crucial to maximizing the performance of fiber cement insulated siding. While it can be installed by experienced DIYers, professional installation is recommended to ensure weather-tightness and code compliance.

Pre-Installation Preparation

Before any siding goes up, the wall structure must be assessed and prepared. This includes checking for sheathing integrity, moisture barriers, and insulation continuity.

- Inspect existing wall for rot, mold, or structural damage

- Install a weather-resistant barrier (WRB) like housewrap

- Ensure all windows and doors are properly flashed

Using a high-quality WRB such as Tyvek or Typar is essential to prevent water infiltration behind the siding.

Step-by-Step Installation Guide

Once the prep work is complete, the siding can be installed in a systematic way:

- Start with starter strips at the bottom edge

- Install panels horizontally, overlapping from bottom to top

- Use corrosion-resistant nails or screws at recommended intervals

- Seal joints and penetrations with compatible caulking

- Install trim and corner boards for a finished look

It’s important to follow the manufacturer’s instructions precisely, as improper fastening can lead to warping or gaps.

Common Installation Mistakes to Avoid

Even experienced contractors can make errors that compromise performance:

- Over-driving fasteners, which can crack the cement board

- Skipping the WRB or using incompatible materials

- Not allowing for expansion gaps in hot climates

- Improper flashing around windows and doors

These mistakes can lead to water intrusion, reduced insulation effectiveness, and premature failure.

Cost Analysis: Is Fiber Cement Insulated Siding Worth It?

While fiber cement insulated siding has a higher upfront cost than traditional options, its long-term value often justifies the investment.

Material and Labor Costs

On average, fiber cement insulated siding costs between $8 and $14 per square foot installed. This includes materials, labor, and flashing.

- Material cost: $5–$9/sq ft

- Labor cost: $3–$5/sq ft

- Total for a 1,500 sq ft home: $12,000–$21,000

For comparison, standard vinyl siding costs $3–$7/sq ft, while non-insulated fiber cement runs $6–$10/sq ft.

Long-Term Savings and ROI

The real value lies in long-term savings. Homeowners can expect:

- 15–20% reduction in energy bills

- Minimal maintenance costs (no painting every 5–7 years)

- Increased home resale value

A study by James Hardie found that homes with fiber cement siding sell for 3.1% more than comparable homes with vinyl siding.

Financing and Incentives

Many utility companies and government programs offer rebates for energy-efficient upgrades. Fiber cement insulated siding may qualify for:

- Federal tax credits under the Inflation Reduction Act

- State-level energy efficiency rebates

- Utility company incentives for insulation improvements

Check the U.S. Department of Energy’s tax credit database for current offers.

Top Brands and Product Comparisons

Several manufacturers offer fiber cement insulated siding, each with unique features and warranties.

James Hardie: HardieZone Insulated Siding

James Hardie is a market leader in fiber cement products. Their HardieZone line is tailored to regional climate needs, offering different insulation levels based on geographic zones.

- R-3.8 insulation value

- ColorPlus technology for fade-resistant finishes

- 30-year limited warranty

Learn more at James Hardie’s official site.

Alside: MasterEdge Insulated Siding

Alside’s MasterEdge combines fiber cement with a high-density EPS backing. It’s known for its ease of installation and competitive pricing.

- R-2.7 insulation

- Available in multiple profiles and colors

- Transferable lifetime warranty

Visit Alside’s product page for details.

Georgia-Pacific: WeatherSide Insulated Panels

GP’s WeatherSide line offers a cost-effective option with solid performance. It’s ideal for budget-conscious homeowners who still want quality insulation.

- R-2.5 insulation

- Integrated water-resistive barrier

- 25-year warranty

More info at GP Building Solutions.

Maintenance and Care Tips

One of the biggest advantages of fiber cement insulated siding is its low maintenance requirements. However, a little care goes a long way in preserving its appearance and performance.

Cleaning and Inspection

Annual cleaning with a garden hose or low-pressure washer is usually sufficient. For tougher stains, use mild detergent and a soft brush.

- Avoid high-pressure washers, which can damage the surface

- Inspect for cracks, loose fasteners, or pest entry points

- Clean gutters to prevent water splash-back

Repairing Damaged Panels

If a panel is cracked or dented, it can be replaced without affecting the entire wall. The process involves:

- Removing the damaged panel by cutting fasteners

- Sliding out the old piece

- Installing the new panel and resealing joints

Always use manufacturer-approved replacement parts to maintain warranty coverage.

Painting and Refinishing

Fiber cement siding is typically factory-painted, but if repainting is needed after 15–20 years, use 100% acrylic paint designed for masonry surfaces.

- Prime bare areas before painting

- Use a roller or sprayer for even coverage

- Paint in mild weather conditions

Environmental Impact and Sustainability

As green building practices gain traction, the environmental footprint of building materials is under scrutiny. Fiber cement insulated siding performs well in several key areas.

Life Cycle Assessment

A life cycle assessment (LCA) considers the environmental impact from raw material extraction to end-of-life disposal. Fiber cement siding scores favorably due to its durability and energy savings.

- Long lifespan reduces replacement frequency

- Energy savings offset production emissions

- Recyclable at specialized facilities

Recyclability and End-of-Life Options

While not widely recycled in municipal programs, fiber cement can be crushed and reused in road base or new cement products. Some manufacturers offer take-back programs.

- Check with local concrete recycling centers

- Avoid landfill disposal when possible

- Demolition waste can be sorted and repurposed

Indoor Air Quality Benefits

Fiber cement insulated siding contributes to better indoor air quality by preventing moisture intrusion and mold growth. It also doesn’t emit volatile organic compounds (VOCs) once installed.

- No off-gassing of harmful chemicals

- Reduces allergens associated with mold and mildew

- Supports healthy building certifications like LEED

Fiber Cement Insulated Siding vs. Other Siding Types

To fully appreciate the advantages of fiber cement insulated siding, it’s helpful to compare it with other popular options.

Vinyl Siding

Vinyl is cheaper upfront but lacks the durability and insulation value of fiber cement. It can warp in heat, crack in cold, and fade over time.

- Fiber cement is 3x more impact-resistant

- Insulated fiber cement has better R-value

- Vinyl requires more frequent replacement

Wood Siding

Wood offers natural beauty but demands high maintenance. It’s prone to rot, insects, and fire.

- Fiber cement resists pests and decay

- No need for annual sealing or painting

- More fire-resistant than wood

Stucco and Masonry

Stucco and brick are durable but expensive and labor-intensive. They also lack integrated insulation.

- Fiber cement is lighter and easier to install

- Lower cost than full masonry systems

- Better thermal performance with built-in insulation

Is fiber cement insulated siding worth the investment?

Absolutely. While the initial cost is higher, the long-term savings on energy, maintenance, and home value make it a smart choice for most homeowners.

Can I install fiber cement insulated siding myself?

It’s possible for experienced DIYers, but professional installation is recommended due to the weight of the panels and precision required for weatherproofing.

How long does fiber cement insulated siding last?

With proper installation and minimal maintenance, it can last 50 years or more, outperforming most other siding materials.

Does insulated siding work in all climates?

Yes. It performs well in hot, cold, humid, and dry climates. Some manufacturers offer climate-specific products for optimal performance.

Is fiber cement siding eco-friendly?

Yes. It’s made with recycled content, lasts decades, reduces energy use, and can be recycled at the end of its life.

Fiber cement insulated siding is more than just a trendy upgrade—it’s a smart, sustainable solution for modern homes. From energy savings and durability to fire resistance and curb appeal, it checks nearly every box for discerning homeowners. While the upfront cost may be higher than traditional options, the long-term benefits in performance, comfort, and value make it a worthwhile investment. Whether you’re building new or renovating, considering fiber cement insulated siding could be one of the best decisions you make for your home’s future.

Recommended for you 👇

Further Reading: