Vinyl Insulated Siding: 7 Ultimate Benefits You Can’t Ignore

Thinking about upgrading your home’s exterior? Vinyl insulated siding might be the game-changer you’ve been searching for. It combines sleek aesthetics, energy efficiency, and long-term savings—all in one powerful package.

What Is Vinyl Insulated Siding?

Vinyl insulated siding is more than just a pretty face on your home. It’s a modern exterior cladding solution that fuses traditional vinyl siding with a rigid layer of foam insulation bonded directly to the back. This integration creates a thermal barrier that significantly improves a home’s energy performance while maintaining the low-maintenance appeal of standard vinyl.

The Evolution from Traditional Vinyl Siding

Originally, vinyl siding was prized for its affordability and ease of installation. However, it lacked insulating properties, making homes vulnerable to temperature fluctuations. Over time, manufacturers recognized the need for better energy performance, leading to the development of insulated variants.

- Traditional vinyl siding offered durability but minimal insulation (R-value of ~0.6).

- Insulated versions now provide R-values between 2.0 and 3.5, depending on thickness and material.

- The innovation bridges the gap between cost-effective cladding and energy-efficient building standards.

How Vinyl Insulated Siding Works

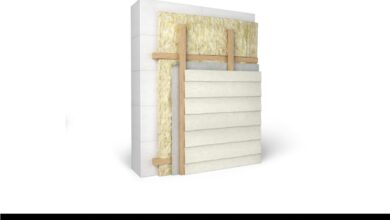

The secret lies in its composite structure. Each panel consists of two main components: the outer vinyl layer and the inner foam backing—typically expanded polystyrene (EPS). This foam layer acts as a continuous insulation blanket across the wall surface.

Unlike cavity insulation, which can have gaps or thermal bridging through studs, vinyl insulated siding provides a more uniform thermal envelope. This reduces air infiltration and minimizes heat loss during winter and heat gain during summer.

“Insulated siding can improve a wall’s overall R-value by up to 20%, according to the U.S. Department of Energy.”

Vinyl Insulated Siding: Key Components and Materials

To truly appreciate the value of vinyl insulated siding, it’s essential to understand its construction. Each panel is engineered for performance, durability, and aesthetic flexibility.

Vinyl Outer Layer: Durability Meets Design

The outer shell is made from polyvinyl chloride (PVC), a resilient plastic known for its resistance to moisture, rot, and insect damage. Modern manufacturing techniques allow for textured finishes that mimic wood, cedar shakes, or even stone.

- Available in a wide range of colors that resist fading due to UV exposure.

- Impact-resistant formulations reduce the risk of dents from hail or debris.

- Interlocking panels ensure tight seams, minimizing air and water penetration.

Insulation Backing: The Thermal Engine

The foam insulation attached to the back of each panel is typically made from expanded polystyrene (EPS), though some premium products use extruded polystyrene (XPS) for higher density and moisture resistance.

EPS is lightweight, cost-effective, and provides excellent thermal resistance per inch. The R-value of EPS ranges from 3.6 to 4.2 per inch, making even thin layers effective. When bonded to vinyl, it creates a rigid, stable panel that enhances structural rigidity.

- EPS is recyclable and widely used in green building applications.

- Some manufacturers add reflective coatings to boost radiant barrier performance.

- The insulation remains effective for decades without settling or degradation.

Attachment System and Installation Hardware

Proper installation is critical. Vinyl insulated siding uses a nailing hem system that allows for expansion and contraction with temperature changes. Installers must follow manufacturer guidelines to avoid buckling or warping.

Specialized clips and furring strips may be used in retrofit applications to ensure proper alignment and drainage. The use of starter strips, J-channels, and corner posts ensures clean transitions around windows, doors, and edges.

Learn more about proper installation techniques at Energy.gov’s guide to insulated siding.

Top 7 Benefits of Vinyl Insulated Siding

Vinyl insulated siding isn’t just another cladding option—it’s a smart investment in your home’s comfort, efficiency, and long-term value. Here’s why homeowners and builders are making the switch.

1. Superior Energy Efficiency

One of the standout advantages of vinyl insulated siding is its ability to reduce energy consumption. By adding a continuous layer of insulation to the exterior, it minimizes thermal bridging—the process where heat escapes through wall studs.

Studies by the National Association of Home Builders (NAHB) show that homes with insulated siding can see heating and cooling costs drop by 10% to 20%. This translates to real savings on utility bills year after year.

- Reduces air leakage by sealing the building envelope.

- Improves indoor comfort by maintaining consistent interior temperatures.

- Complements other insulation like fiberglass or spray foam for maximum efficiency.

2. Enhanced Comfort and Indoor Air Quality

Beyond energy savings, vinyl insulated siding contributes to a more comfortable living environment. The added insulation dampens outside noise, making homes quieter—especially in urban or busy areas.

It also helps prevent condensation within wall cavities, which can lead to mold and mildew growth. By keeping walls warmer in winter, the dew point is less likely to be reached inside the wall assembly.

- Reduces exterior noise by up to 30%, according to acoustic testing.

- Minimizes drafts and cold spots near exterior walls.

- Supports healthier indoor environments by reducing moisture-related issues.

3. Long-Term Cost Savings

While the upfront cost of vinyl insulated siding is higher than standard vinyl—typically 20% to 30% more—the long-term return on investment is compelling. Lower energy bills, reduced maintenance, and increased home value offset the initial expense.

Additionally, many utility companies and government programs offer rebates or tax incentives for energy-efficient home improvements. For example, the U.S. federal tax credit for energy-efficient home improvements can cover up to 30% of qualifying costs through 2032 under the Inflation Reduction Act.

- Potential savings of $200–$500 annually on energy bills.

- Eligibility for green energy tax credits and local utility rebates.

- Increased resale value—homes with energy-efficient features sell faster and at higher prices.

4. Low Maintenance and Durability

Vinyl insulated siding requires minimal upkeep. Unlike wood, it doesn’t need painting, sealing, or staining. A simple rinse with a garden hose is usually enough to keep it looking fresh.

The material is resistant to rot, termites, and fungal decay. High-quality products come with warranties ranging from 20 to 50 years, reflecting confidence in their longevity.

- No painting or scraping required over the lifespan of the siding.

- Resists chipping, cracking, and warping under normal conditions.

- Easy to repair—individual panels can be replaced without affecting the entire wall.

5. Aesthetic Flexibility and Curb Appeal

Today’s vinyl insulated siding comes in a vast array of styles, colors, and textures. Whether you prefer the rustic charm of cedar shake or the clean lines of horizontal lap siding, there’s a design to match every architectural style.

Manufacturers like Mastic, Alside, and CertainTeed offer premium lines with deep embossing, shadow lines, and multi-tone finishes that add depth and realism to the façade.

- Available in over 50 color options, including fade-resistant formulations.

- Textured finishes mimic natural materials without the maintenance.

- Can be combined with accent trims, soffits, and fascia for a custom look.

6. Environmental and Sustainability Advantages

Vinyl insulated siding supports sustainable building practices in several ways. First, its energy-saving properties reduce greenhouse gas emissions from heating and cooling systems.

Second, the production process has become more eco-friendly, with manufacturers using recycled content and reducing energy consumption in extrusion. Some brands now offer panels made with up to 30% recycled vinyl.

- Lowers carbon footprint by reducing energy demand.

- Recyclable at end-of-life in specialized facilities.

- Reduces reliance on non-renewable energy sources.

7. Increased Home Value and Marketability

Upgrading to vinyl insulated siding can boost your home’s market value. Real estate professionals often highlight energy-efficient features as major selling points.

According to Remodeling Magazine’s 2023 Cost vs. Value Report, siding replacements recoup over 80% of their cost at resale. Insulated versions typically command a higher return due to their performance benefits.

- Improves energy efficiency ratings, appealing to eco-conscious buyers.

- Enhances curb appeal, making homes stand out in competitive markets.

- Reduces perceived maintenance costs for future owners.

Vinyl Insulated Siding vs. Other Siding Options

With so many siding materials on the market, how does vinyl insulated siding stack up against the competition? Let’s compare it to common alternatives.

Vinyl Insulated Siding vs. Fiber Cement

Fiber cement (e.g., James Hardie) is durable and fire-resistant but heavier and more labor-intensive to install. It also lacks built-in insulation, requiring separate sheathing or cavity insulation.

- Vinyl insulated siding is lighter and faster to install.

- Fiber cement is more resistant to impact but can crack in freeze-thaw cycles.

- Vinyl offers better thermal performance when insulation is included.

Vinyl Insulated Siding vs. Wood Siding

Wood offers natural beauty but demands high maintenance—regular painting, sealing, and vulnerability to rot and pests. Vinyl insulated siding mimics wood aesthetics without the upkeep.

- Vinyl is immune to termites and fungal decay.

- No need for annual staining or repainting.

- More consistent color retention over time.

Vinyl Insulated Siding vs. Metal Siding

Metal siding (steel or aluminum) is strong and fireproof but can dent easily and conduct heat, reducing energy efficiency unless paired with insulation.

- Vinyl insulated siding provides built-in thermal resistance.

- Metal may require additional underlayment for noise reduction.

- Vinyl is quieter during rain and hail events.

Installation Process: What to Expect

Installing vinyl insulated siding is a precise process that should be handled by trained professionals. While DIY installation is possible, improper techniques can lead to gaps, buckling, or water intrusion.

Pre-Installation Assessment

Before any panels go up, a thorough inspection of the existing wall structure is essential. This includes checking for:

- Rot, moisture damage, or insect infestation in sheathing.

- Proper housewrap or weather-resistant barrier (WRB) installation.

- Alignment of windows, doors, and corners for seamless integration.

If the existing siding is in poor condition, it should be removed to allow for repairs and the application of a new moisture barrier.

Step-by-Step Installation Guide

Professional installers follow a standardized sequence to ensure durability and performance:

- Install starter strip at the bottom edge to support the first row.

- Apply J-channels around windows, doors, and corners.

- Begin at the bottom, working upward with overlapping panels.

- Nail correctly in the nailing hem, leaving room for expansion.

- Stagger seams between rows to prevent water infiltration.

- Finish with trim pieces and inspect for alignment.

Proper flashing around rooflines and penetrations is critical to prevent leaks.

Common Installation Mistakes to Avoid

Even experienced contractors can make errors that compromise performance:

- Over-nailing: Too many nails restrict expansion, causing buckling.

- Improper nailing height: Nails must be centered in the nailing hem.

- Ignoring expansion gaps: Panels need space to move with temperature changes.

- Poor flashing: Leads to water intrusion and potential rot.

For best practices, refer to the Vinyl Siding Institute’s installation guidelines.

Maintenance and Longevity of Vinyl Insulated Siding

One of the biggest selling points of vinyl insulated siding is its low maintenance. However, a little care goes a long way in preserving its appearance and performance.

Regular Cleaning Tips

To keep your siding looking its best, clean it at least once a year:

- Use a soft-bristle brush or low-pressure washer (under 1,500 PSI).

- Mix mild detergent with water—avoid harsh chemicals like bleach.

- Rinse thoroughly to remove soap residue.

For stubborn stains like algae or mildew, a solution of 30% vinegar and 70% water can be effective.

Inspecting for Damage

Seasonal inspections help catch issues early:

- Look for cracks, warping, or loose panels.

- Check around windows and doors for gaps or moisture signs.

- Ensure downspouts and gutters aren’t directing water onto the siding.

If a panel is damaged, it can usually be removed and replaced without affecting adjacent sections.

Handling Repairs and Replacements

Minor dents or scratches can often be repaired with heat (using a hairdryer) to reshape the vinyl. For larger damage, replacement is straightforward:

- Remove the damaged panel by releasing the interlock above it.

- Slide in the new panel and relock it into place.

- Re-nail if necessary, following manufacturer specs.

Always keep leftover panels from the original installation for color matching.

Vinyl Insulated Siding and Energy Efficiency Standards

As building codes evolve toward greater energy efficiency, vinyl insulated siding is gaining recognition as a valuable component of high-performance homes.

Meeting Building Code Requirements

Modern energy codes, such as the International Energy Conservation Code (IECC), require continuous insulation in many climate zones. Vinyl insulated siding contributes to this requirement by providing a layer of exterior insulation.

- Helps meet R-value mandates for walls in Zones 4–8.

- Reduces thermal bridging through framing members.

- Can be used in conjunction with cavity insulation for higher performance.

Contribution to Green Building Certifications

Vinyl insulated siding can contribute points toward green building certifications like ENERGY STAR, LEED, and Passive House standards.

- ENERGY STAR: Qualifies as part of an energy-efficient envelope.

- LEED: Contributes to energy and atmosphere credits.

- Passive House: Helps achieve ultra-low heating demand targets.

When combined with air sealing and high-performance windows, insulated siding plays a key role in creating net-zero energy homes.

Real-World Energy Performance Data

A 2020 study by the Oak Ridge National Laboratory found that homes with insulated siding experienced a 12% reduction in heating load compared to those with standard vinyl. Cooling loads were reduced by 8% in hot climates.

Another field study in Minnesota showed indoor temperature fluctuations decreased by 3–5°F, enhancing comfort without additional HVAC capacity.

Explore energy performance data at ORNL’s research page.

Choosing the Right Vinyl Insulated Siding for Your Home

With multiple brands, styles, and price points, selecting the best vinyl insulated siding requires careful consideration.

Top Brands and Product Lines

Reputable manufacturers offer high-quality insulated siding with strong warranties:

- Mastic by Ply Gem: Known for durability and fade resistance.

- Alside: Offers the Prodigy line with high R-values and deep textures.

- CertainTeed: Provides the Monogram line with excellent impact resistance.

- Georgia-Pacific: Revere Premium Insulated Siding with integrated foam.

Always check warranty terms—look for lifetime coverage on materials and fading.

Factors to Consider Before Buying

Before making a decision, evaluate:

- Climate zone and insulation needs.

- Budget and long-term savings goals.

- Aesthetic preferences and neighborhood guidelines.

- Installer experience and certification.

Request samples to see color and texture in natural light.

Cost Analysis: What to Expect

The average cost of vinyl insulated siding ranges from $7 to $12 per square foot installed, compared to $4 to $8 for standard vinyl.

- Total cost for a 1,500 sq. ft. home: $10,500–$18,000.

- Premium brands and complex designs increase costs.

- DIY can save labor but risks improper installation.

Factor in potential energy savings and tax credits when evaluating ROI.

Is vinyl insulated siding worth the investment?

Absolutely. For most homeowners, the combination of energy savings, durability, and curb appeal makes it a smart long-term upgrade.

How much energy can I save with vinyl insulated siding?

Most homeowners see a 10% to 20% reduction in heating and cooling costs, depending on climate and home insulation levels.

Can vinyl insulated siding be installed over existing siding?

Yes, in many cases—but only if the existing siding is in good condition and flat. Otherwise, removal is recommended to inspect and repair sheathing.

Does insulated siding require special maintenance?

No, it requires the same minimal maintenance as standard vinyl—occasional cleaning and visual inspections.

Is vinyl insulated siding environmentally friendly?

Yes. It reduces energy consumption, can contain recycled content, and is recyclable at specialized facilities.

Choosing vinyl insulated siding is more than a cosmetic upgrade—it’s a strategic move toward a more efficient, comfortable, and valuable home. With its blend of performance, durability, and aesthetic versatility, it stands out as one of the smartest exterior cladding choices available today. Whether you’re building new or remodeling, this innovative product delivers real benefits that last for decades.

Further Reading: