Wood Insulated Siding: 7 Ultimate Benefits You Can’t Ignore

Thinking about upgrading your home’s exterior? Wood insulated siding might be the game-changer you’ve been searching for. It blends timeless beauty with modern energy efficiency, offering homeowners a smart, sustainable solution that looks as good as it performs.

What Is Wood Insulated Siding?

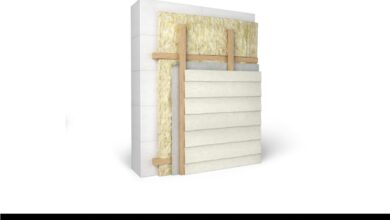

Wood insulated siding is a high-performance exterior cladding that combines the natural elegance of wood with advanced insulation technology. Unlike traditional wood siding, this innovative material integrates a rigid foam or mineral wool insulation layer directly bonded to the back of wood panels, enhancing thermal performance without sacrificing aesthetics.

How It Differs from Traditional Wood Siding

Traditional wood siding, while visually appealing, often lacks built-in insulation. Homeowners typically need to install separate insulation behind the sheathing, which can create thermal bridging and reduce overall efficiency. Wood insulated siding eliminates this gap by merging structure and insulation into a single, seamless unit.

- Traditional siding requires separate vapor and insulation layers.

- Insulated versions offer integrated thermal resistance (R-value).

- Reduced labor and material costs during installation.

Core Components and Structure

The typical construction of wood insulated siding includes three main layers: a premium wood exterior (often cedar, redwood, or engineered wood), a high-density insulation core (usually EPS, XPS, or mineral wool), and a weather-resistant backing membrane. This sandwich design maximizes durability, moisture resistance, and energy savings.

“The integration of insulation into cladding systems represents the future of sustainable building design.” — Building Science Institute, buildingscience.com

Top 7 Benefits of Wood Insulated Siding

Choosing wood insulated siding isn’t just about curb appeal—it’s a strategic investment in comfort, efficiency, and long-term value. Here are seven compelling reasons why this material is gaining popularity among architects, builders, and eco-conscious homeowners.

1. Superior Energy Efficiency

One of the standout advantages of wood insulated siding is its ability to significantly reduce heating and cooling costs. With integrated insulation layers offering R-values between R-4 and R-7.5 per inch, these panels minimize heat transfer through walls.

- Reduces air infiltration by up to 40% compared to non-insulated cladding.

- Helps maintain consistent indoor temperatures year-round.

- Contributes to lower HVAC system strain and energy bills.

According to the U.S. Department of Energy, proper exterior insulation can cut energy use by 15–25%. When combined with air sealing techniques, wood insulated siding becomes a cornerstone of high-performance homes. Learn more at energy.gov.

2. Enhanced Thermal Comfort

Beyond energy savings, wood insulated siding improves indoor comfort. Cold spots near exterior walls are minimized, and radiant temperature balance is improved, making rooms feel warmer in winter and cooler in summer—even at lower thermostat settings.

- Eliminates drafts caused by thermal bridging.

- Increases surface temperature of interior walls.

- Improves overall livability, especially in older homes.

3. Noise Reduction and Sound Dampening

The dense insulation core acts as a sound barrier, reducing external noise from traffic, neighbors, or weather. This acoustic benefit is particularly valuable in urban or high-traffic areas.

- Can reduce sound transmission by up to 10–15 decibels.

- Improves privacy and concentration indoors.

- Especially effective when paired with double-glazed windows.

4. Increased Home Value and Curb Appeal

Wood siding has long been associated with premium homes, and adding insulation enhances its market appeal. Homes with energy-efficient features sell faster and at higher prices, according to the National Association of Realtors.

- Boosts perceived quality and craftsmanship.

- Attracts environmentally conscious buyers.

- Can increase resale value by 5–10% in competitive markets.

For more insights on home value trends, visit nar.realtor.

5. Moisture and Mold Resistance

Modern wood insulated siding systems are engineered with drainage planes and moisture-resistant barriers. These features allow any water that penetrates the surface to escape quickly, preventing rot and mold growth.

- Back-ventilated designs promote airflow behind panels.

- Mineral wool cores resist water absorption better than foam.

- Reduces long-term maintenance and repair costs.

6. Sustainability and Eco-Friendliness

Wood is a renewable resource, and when sourced responsibly, it has a lower carbon footprint than vinyl or fiber cement. Insulated siding further enhances sustainability by reducing energy consumption over the home’s lifetime.

- Wood sequesters carbon dioxide during growth.

- Insulation reduces reliance on fossil fuels for heating.

- Many manufacturers offer FSC-certified wood options.

Explore sustainable forestry practices at fsc.org.

7. Long-Term Durability and Low Maintenance

When properly installed and maintained, wood insulated siding can last 30–50 years. The insulation layer protects the wall assembly from temperature swings, reducing expansion and contraction stress on the wood.

- Resists warping, cracking, and splitting better than bare wood.

- Requires only periodic cleaning and resealing.

- Modern finishes offer UV and insect resistance.

Types of Wood Insulated Siding Available

Not all wood insulated siding is created equal. Different materials, construction methods, and insulation types offer varying levels of performance, cost, and aesthetic appeal. Understanding your options helps you make an informed decision.

Solid Wood with Applied Insulation Panels

This method involves installing traditional wood clapboard or shingle siding over a continuous layer of rigid insulation board (like XPS or mineral wool). While not factory-integrated, this approach offers flexibility in design and material choice.

- Allows for custom wood species and finishes.

- Requires skilled installation to avoid thermal bridging.

- Common in high-end custom homes.

Prefabricated Insulated Wood Panels

These are factory-made panels where wood veneer or solid wood is laminated to a rigid insulation core. They come in large sheets or planks, designed for rapid installation and consistent performance.

- High R-values with minimal thickness.

- Available in various textures: smooth, rustic, board-and-batten.

- Used in both residential and commercial projects.

Brands like Kingspan and Alsecco lead in this space, offering precision-engineered insulated wood systems.

Engineered Wood with Integrated Insulation

Engineered wood products (like oriented strand board or laminated veneer lumber) are combined with insulation to create cost-effective, stable siding solutions. These are ideal for large surface areas and modern architectural styles.

- Less prone to swelling or shrinking than solid wood.

- Can be pre-finished with paint or stain.

- Often used in Passive House and net-zero energy projects.

Installation Process and Best Practices

Proper installation is critical to maximizing the performance of wood insulated siding. Even the best materials can underperform if installed incorrectly. Here’s what you need to know.

Pre-Installation Preparation

Before any panels go up, the wall structure must be sound. This includes checking for structural integrity, installing a proper weather-resistive barrier (WRB), and ensuring all windows and doors are properly flashed.

- Use breathable WRBs like Tyvek or Delta-Dry.

- Install furring strips for a ventilated rainscreen gap.

- Seal all joints and penetrations with compatible tapes or sealants.

Step-by-Step Installation Guide

1. Start with a starter strip at the bottom edge.

2. Align the first panel, ensuring it’s level.

3. Fasten with corrosion-resistant screws or nails at recommended intervals.

4. Stagger joints between rows to prevent water infiltration.

5. Install trim and corner pieces with integrated flashing.

6. Seal all seams with backer rod and high-quality exterior caulk.

- Always follow manufacturer specifications.

- Use a rainscreen gap of at least 3/8 inch for airflow.

- Avoid compressing the insulation layer during fastening.

Common Installation Mistakes to Avoid

Even experienced contractors can make errors that compromise performance. The most frequent issues include improper flashing, lack of ventilation, and inadequate sealing.

- Skipping the rainscreen gap leads to moisture trapping.

- Over-tightening fasteners can crush insulation and reduce R-value.

- Using incompatible sealants may degrade over time.

“A perfect wall assembly is only as strong as its weakest detail.” — Joseph Lstiburek, Building Science Corporation

Maintenance Tips for Longevity

While wood insulated siding is designed for durability, regular maintenance ensures it performs optimally for decades. Unlike vinyl or metal, wood requires periodic care to preserve its appearance and structural integrity.

Cleaning and Inspection Schedule

Inspect your siding at least twice a year—spring and fall—for signs of damage, mold, or pest activity. Clean with a soft brush and mild detergent, avoiding pressure washers that can force water behind panels.

- Remove dirt, mildew, and debris buildup.

- Check for loose fasteners or cracked wood.

- Ensure drainage channels remain unobstructed.

Re-Sealing and Refinishing

Wood finishes degrade over time due to UV exposure and weather. Most manufacturers recommend re-sealing every 5–7 years, depending on climate and sun exposure.

- Use water-repellent preservatives with UV inhibitors.

- Sand lightly before applying new finish.

- Choose breathable finishes to avoid moisture trapping.

Dealing with Moisture and Pest Issues

While modern systems are highly resistant, wood can still attract termites or carpenter ants if conditions are favorable. Prevent infestations by keeping vegetation away from the foundation and fixing leaks promptly.

- Install metal termite shields during construction.

- Treat wood with borate-based preservatives.

- Monitor for sawdust or hollow-sounding wood.

Cost Analysis: Is Wood Insulated Siding Worth It?

Investing in wood insulated siding involves higher upfront costs than standard siding, but the long-term savings and benefits often justify the expense. Let’s break down the numbers.

Material and Installation Costs

Wood insulated siding typically costs between $12 and $25 per square foot installed, depending on the type, insulation level, and regional labor rates. This compares to $6–$12 for standard wood siding and $3–$8 for vinyl.

- Prefabricated panels are more expensive but save on labor.

- Custom installations with rare wood species increase cost.

- Additional expenses may include structural upgrades or scaffolding.

Return on Investment (ROI)

While the initial investment is higher, the ROI on wood insulated siding can be substantial. Energy savings alone can recoup 50–70% of the cost over 10–15 years, according to the U.S. Environmental Protection Agency’s ENERGY STAR program.

- Reduces annual energy bills by 10–20%.

- Increases home resale value.

- Qualifies for tax credits and rebates in some regions.

Check available incentives at energystar.gov.

Comparison with Other Siding Options

How does wood insulated siding stack up against alternatives? Here’s a quick comparison:

- Vinyl siding: Cheaper but less insulating and durable.

- Fiber cement: Durable and fire-resistant but heavy and non-insulating.

- Stucco: High maintenance and prone to cracking.

- Metal siding: Long-lasting but conducts heat and can dent.

Wood insulated siding offers a balanced blend of beauty, performance, and sustainability that few alternatives match.

Environmental Impact and Sustainability

In an era of climate awareness, the environmental footprint of building materials matters more than ever. Wood insulated siding stands out as a responsible choice when sourced and installed correctly.

Carbon Sequestration and Renewable Resources

Wood is one of the few building materials that actively removes carbon dioxide from the atmosphere. A typical wood-framed house stores about 20–30 tons of CO2. When combined with insulation, the net carbon benefit is even greater due to reduced operational emissions.

- Sustainably managed forests regenerate and absorb more CO2.

- Manufacturing wood products uses less energy than steel or concrete.

- Biodegradable at end of life, unlike synthetic sidings.

Life Cycle Assessment (LCA) of Wood Insulated Siding

Life cycle assessments measure environmental impact from raw material extraction to disposal. Studies show that wood-based insulated systems have lower global warming potential than most cladding options.

- Low embodied energy in production.

- Long service life reduces replacement frequency.

- Recyclable or compostable components at end-of-life.

For detailed LCA data, refer to the Athena Institute’s Sustainable Materials Database.

Responsible Sourcing and Certifications

To ensure your wood insulated siding is truly sustainable, look for certifications like FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), or PEFC (Programme for the Endorsement of Forest Certification).

- FSC certification ensures no deforestation or habitat destruction.

- Third-party audits verify chain-of-custody standards.

- Many European manufacturers exceed North American standards.

Real-World Case Studies and Success Stories

Theoretical benefits are one thing, but real-world performance is what truly matters. Let’s look at a few examples where wood insulated siding made a measurable difference.

Case Study 1: Net-Zero Home in Vermont

A custom home in Burlington, VT, used prefabricated wood insulated panels with R-7.5 mineral wool cores. Combined with solar panels and air sealing, the home achieved net-zero energy status. Annual heating costs dropped from $1,800 to under $300.

- Installed in just 5 days due to panelized system.

- Homeowner reported improved comfort and quietness.

- Project featured in Green Building Advisor.

Case Study 2: Urban Renovation in Seattle

An older craftsman home in Seattle was retrofitted with solid cedar siding over rigid XPS insulation. The rainscreen design prevented moisture issues common in the rainy Pacific Northwest.

- Reduced energy use by 22% in first year.

- Eliminated mold problems in exterior walls.

- Increased home value by $45,000 after renovation.

Case Study 3: Passive House in Colorado

A high-altitude Passive House project used engineered wood insulated panels to meet strict airtightness and thermal performance standards. The system contributed to a heating demand of just 1.5 kWh/m²/year.

- Met PHIUS+ certification requirements.

- Withstood extreme temperature swings (-20°F to 90°F).

- Demonstrated durability in snow and wind loads.

What is wood insulated siding made of?

Wood insulated siding typically consists of a wood exterior layer (solid or engineered), a rigid insulation core (such as EPS, XPS, or mineral wool), and a weather-resistant backing. These layers are bonded together to form a single, high-performance panel.

How much does wood insulated siding cost?

Installed costs range from $12 to $25 per square foot, depending on materials, insulation type, and labor. While more expensive than standard siding, the long-term energy savings and durability often justify the investment.

Is wood insulated siding good for cold climates?

Yes, it’s excellent for cold climates. The integrated insulation reduces heat loss, prevents thermal bridging, and improves indoor comfort. Its performance is especially valuable in regions with harsh winters and high heating demands.

How long does wood insulated siding last?

With proper installation and maintenance, wood insulated siding can last 30 to 50 years. Regular cleaning, re-sealing, and inspections help extend its lifespan and preserve its appearance.

Can I install wood insulated siding myself?

While DIY installation is possible for experienced homeowners, professional installation is recommended. Proper flashing, sealing, and rainscreen detailing are critical to performance and longevity.

Wood insulated siding represents a powerful fusion of natural beauty and modern engineering. It delivers exceptional energy efficiency, long-term durability, and environmental benefits that few other cladding systems can match. Whether you’re building new or renovating, this innovative material offers a smart, sustainable choice that enhances both comfort and value. By understanding its benefits, types, and best practices, homeowners can make informed decisions that pay off for decades.

Recommended for you 👇

Further Reading: